What’s the hurry with CSG fracking?

COAL FORMS OVER aeons of time from dead vegetation buried under layers of sand, silt and clay at depths where it is compressed and heated to temperatures from 100°C to 200°C. As it changes into peat and then coal, gas is released (made up of methane, carbon dioxide and other constituents). Some of this remains trapped in the layers, and this is what we call coal seam gas or CSG – it’s the gas that’s responsible for explosions in traditional coalmining.

Exploration of unconventional gas sources, such as CSG and shale gas, has grown rapidly since the mid-1990s as consumption has increased and Australia moves towards a lower carbon economy. All are found in complex geological systems and demand technical innovation to extract safely and economically. CSG is contentious because exploration pre-empts drilling and production in locations that house communities or have other land uses, such as agriculture and forestry.

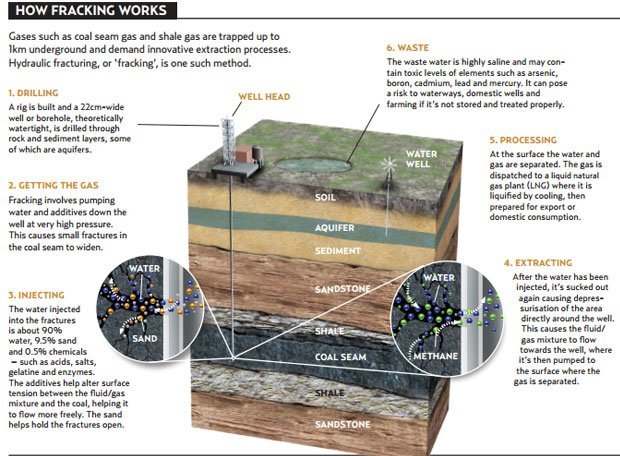

The drilling of 500 gas wells, for example, is proposed in the Pilliga State Forest in northern NSW – the only known habitat of the rare Pilliga mouse. In the catchments of the Condamine and Namoi rivers – both tributaries of the Murray–Darling river system – CSG exploration is already underway in close proximity to some of the nation’s most productive farmland. Agriculture depends on both surface and ground water, and there are worries that fracking – the process by which the gas is extracted (see graphic, below) – could contaminate both.

How fracking works

The need for CSG rising

There are serious concerns, nationally and locally, about CSG production, including increases to our greenhouse gas footprint (relative to renewable energy sources), leaking wells contaminating freshwater aquifers, and the impact of thousands of wells and kilometres of pipeline that could adversely affect large tracts of land.

At the moment, CSG is a small contributor to our total energy needs, but the sector is growing rapidly. In 2000, just 3 petajoules of energy was produced in Australia using CSG, but by 2010 that had ballooned to 221 petajoules. Government forecasts suggest that CSG will account for almost one quarter (23.6 per cent) of energy produced from 15 new energy projects proposed during 2010. Much of the CSG will be converted into liquid natural gas (LNG) and exported to Asia, with major buyers including China, India and Japan.

CSG’s huge potential comes as a result of Australia’s extensive coal deposits stretching for many thousands of square kilometres beneath our cities, farmlands and national parks. Our major coal seams run for more than 1500km from Wollongong in NSW, to Collinsville in central Queensland with other significant coal resources across all states.

There are, of course, economic and social benefits that will come from CSG mining. In Australia, many key gas extraction sites are close to local domestic users. The industry will create jobs – and there’s the potentially lucrative export market. Billions of dollars have already been invested in CSG, and it will develop into an active sector in the foreseeable future, yet there remains sizeable gaps in our knowledge of the environmental, health and socio-economic costs of extracting it.

Coals not created equal

Not all coals are the same; deposits have developed under a range of geological conditions requiring a variety of extraction methods, all with, as yet, unknown after-effects.

The wells, or boreholes, built to access the gas can be either vertical, or curved using ‘directional drilling’ to follow undulating coal seams. These seams have numerous small fractures that are usually tight, limiting the movement of gas and fluid. The width of these fractures is increased using a process known as ‘hydraulic fracturing’ or ‘fracking’, which releases trapped fluids, enhancing gas drainage from the seam. Fracking involves injecting water, sand and small amounts of chemical additives (including acids, salts, gelatine and enzymes) into the well under extremely high pressure, which then expands the fractures in the coal seams.

The additives help alter the surface tension between the fluid and the coal, enhancing its mobility through the fracture network – they also dissolve minerals, stabilise the clays and prevent corrosion. The grains of sand prop open the fractures, improving the effectiveness of the extraction technique. The area around the well is subsequently depressurised, causing water and gas to flow back towards the well from where it’s extracted to the surface.

The long-term ramifications of those chemical additives leaking into adjacent freshwater aquifers are as yet unknown, and hydraulic fracturing has been linked to small earthquakes in England and the USA. Plans for CSG exploratory drilling in heavily populated urban areas, like that proposed for the suburb of St Peters in Sydney, are causing genuine community alarm.

The impacts of a CSG well are not only felt in the immediate locality. The influence of depressurisation can extend horizontally for several kilometres through a seam. Usually the change in pressure between vertical layers is minimal – but if the rocks are permeable or cracked, then, over years or decades, overlying aquifers could be affected, potentially lowering water levels and ultimately impacting irrigation and domestic wells. If we subsequently find out that CSG was the cause, nothing could be done in the short term to restore water levels in affected wells. It would take decades – perhaps even centuries – to restore pressures throughout aquifers.

The problem with CSG wastewater

Some CSG wells, in particular in Queensland, will produce tens of millions of litres of waste water each year. Much of this water is saline and, if released, has the potential to alter the temperature, acidity and chemistry of local streams and lakes, wiping out plants and animals. Even with best practices adopted, accidents still happen. In the Pilliga, for example, thousands of litres of saline water have already been released, killing trees near one CSG drilling site. The chemistry of untreated saline water can cause topsoils to break down and wash away so, in this form, it can’t be recycled for agriculture. To date, most CSG waste has been stored in ponds, but this is an unsatisfactory solution. As the water evaporates, the salts in it concentrate, forming brines. Over time, there’s a risk that the ponds will leak into underlying aquifers, or the brines will escape into the surface water during floods.

Proposed solutions include reinjecting waste water into deep aquifers; it’s a possible answer, but not yet available on the scale required to be effective. Waste water can also be purified using membrane or thermal techniques – but these use energy and therefore raise the greenhouse footprint of CSG, while still leaving behind the salt element to be disposed of in landfills.

Two extensive research projects in the USA, including one by the Environmental Protection Agency (EPA), detected unsafe levels of methane in groundwater up to 1km away from gas-production sites. Methane rapidly escapes from water when it reaches the surface, adding to greenhouse gases, and, if contaminated groundwater is used for domestic water supply, hazardous methane gas can build up to explosive levels in homes. However, while this has happened in the USA, the risk is extremely low here in Australia.

Although CSG produces less carbon dioxide than coal during power generation, overall benefits in terms of greenhouse gas reduction may be negligible.

However, if we regard CSG as a transitional fuel along the path to renewable energy, then there are locations in Australia where it could be extracted safely by adhering to best practice processes, and consequently minimising the environmental impact. Wells could be limited to degraded farmland and localities where it can be extracted with low volumes of water. To speed up the shift to renewable energy, more government and industry support is needed for research into these options.

Our regulatory framework is playing catch-up: creating guidelines on the fly and trialling different ways to get rid of waste water safely, while also expediting new developments. This isn’t inspiring confidence in the expansion of the sector, and if mistakes are made, the effects will be felt for generations.

The gas has already sat in the ground for millions of years. Will a few more years of necessary research and diligence on the impacts of the coal seam gas industry hurt anybody?

Bryce is a member of the University of New South Wales Connected Waters Initiative team, investigating the sustainable management of Australia’s groundwater.

Source: Australian Geographic Mar – Apr 2012

RELATED STORIES