Deepsea Challenger: an Australian marvel

THE MARIANA TRENCH in the western Pacific is a foreboding place. Found between Japan and New Guinea, east of the Mariana Islands, It’s the deepest place in all the world’s oceans. Temperatures hover just above freezing, it’s totally dark, and the pressures are incredible.

Last month Hollywood Director James Cameron made history by completing the first solo descent to the Challenger Deep, the trench’s deepest spot, 11km below the surface.

For nearly seven years, he and Australian engineer Ron Allum had been working on a one-of-a-kind submersible that could withstand pressures 1000 times greater than at the surface.

This bright green submarine, dubbed the Deepsea Challenger, was eventually built and assembled at a workshop in Leichhardt in Sydney’s inner west.

Mariana Trench dive

“It was a fantastic experience,” says Ron. “We had a great Australian team. We drew on resources from builders to machinists, to a company in Western Australia that provided the underwater communication for us. All the Australian contingents really pulled together well.”

Ron has been involved in James’ deep-sea expeditions since 2001, but he says creating a machine to pull off an 11km dive was a remarkable achievement. “Certainly I came across hurdles but it was just a matter of finding the right people, developing the right technology, and getting on with it,” he told Australian Geographic.

Scientists know little about the organisms that exist in such extreme ocean environments. One of the aims of the expedition was for James – the creator of films from Titanic to Avatar – was to record footage for a 3D documentary and collect deep-sea specimens for scientific analysis.

Challenger Deep first

Diving to the Challenger Deep hadn’t been attempted since 1960, when naval officer Don Walsh and oceanographer Jacques Piccard went down in their sub, the Trieste. They took five hours to get to the bottom and spent only 20 minutes there.

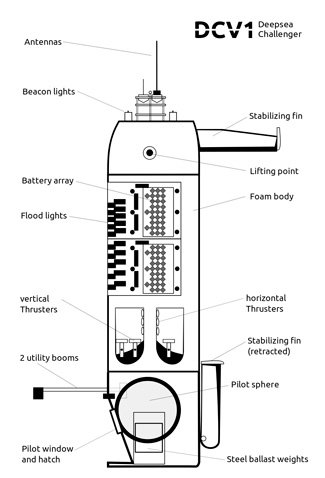

Cameron, however, stayed at the bottom for three hours, and the descent took just over an hour. One of the sub’s truly unique features is that it travels rapidly in an upright position, like an elevator. This leaves more time for exploring the ocean floor, Ron says.

“We thought, ‘well if you’re going to spend most of your time in vertical flight, let’s design it for vertical speed’, so it seemed natural,” he says. The sub also descends quickly thanks to a pack of 450kg iron ballast weights attached to its sides by electromagnets. When this load is dumped, the sub races back to the surface.

Schematic of Deepsea Challenger (Credit: Deepsea Challenge/Zuckerberg)

Coping with crushing pressures

Everything about the sub – from the pilot’s chamber, to the battery packs, to the HD cameras – had to be specially engineered to cope with massive pressures.

“The big challenge was that all the components were shrinking under the pressure but the different materials were shrinking at different rates,” says Dave Goldie, an Aussie mechanical engineer, who was part of the team that went with Cameron to the Pacific.

The length of the vessel itself shrank by as much as 7cm at the deepest point in the dive, Dave says.

Tailor made for the deep

Finding materials that could do the job without crushing wasn’t easy. Hobart – based engineer Phil Durbin was tasked with finalising the design of the sub’s two main components: the steel sphere where the driver sits, and the foam beam which makes up the sub’s structural core.

The team was confident that making the pilot’s chamber orb shaped, rather than cylindrical, would give it the best chance of resisting the pressure. “We’d tested the steel sphere at almost real pressures in a chamber at Penn State in the US,” says Phil. “But the beam hadn’t been down to those pressures until they did an unmanned run not long before James’ dive.”

The foam beam is made of millions of glass microspheres bonded in an epoxy resin, and it’s the only flotation material that can stand the pressure without warping. Phil and Ron had to invent it from scratch, because they couldn’t find what they were looking for anywhere else. It took them 18 months.

“It was a real engineering learning experience for me,” says Ron. “The thing that we thought we could buy off the shelf was the syntactic foam…but the commercial ones that we came across failed to be uniform in density and strength.”

James Cameron’s adventure

During the three hours he spent deep in the Mariana Trench, Cameron filmed what he saw using cameras housed in titanium pressure cases. The largest camera on board the sub is a Red Epic, which captures IMAX-quality images, and projects them onto a screen in front of the pilot’s face.

The sub’s movements are controlled with a joystick. There’s also a hydraulic mechanical arm that collects rocks and sediment from the seafloor, but unfortunately this malfunctioned on Cameron’s dive. Still, he was able to collect samples with the suction gun attached to the bottom of the sub.

The crew are hopeful some of these specimens can provide answers about life in the deep, and about the movement of tectonic plates that create trenches and can cause earthquakes and tsunamis.

Aussie engineers making waves

Dave says it was an exciting project to be a part of, but he’s surprised at how little credit Australians have given to the local team behind it. “If Australians appreciate their engineers like they appreciate their sports people, Ron Allum would have had a tickertape parade,” he says.

Phil Durban says the project created a wonderful opportunity for many engineers. “It really does go to prove that we have inventive talent in Australia,” he says. “Once the dive had been done and they got to the surface ok, I just could sit down at the ocean side and look and the view and think, ‘wow that was pretty cool’.”

Find out more about the Deepsea Challenge expedition here.

RELATED STORIES