Unspinning the secrets of spider webs

A new global study, involving University of New South Wales scientists, has analysed the silk properties of spiders across Oceania, Asia, Europe and the USA to better understand how this natural wonder can be emulated in future biomaterials. The research, published in Science Advances, catalogued the silk gene sequences of 1098 species from 76 families.

“Up until now, there was a pretty good literature set of how spider silk performs,” says Dr Sean Blamires, an evolutionary ecological biologist from UNSW Sydney’s School of Biological, Environmental and Earth Sciences. “But what has been lacking is a way to generalise across spiders and find out what causes specific properties. Is there a link between genes, protein structures and fibres?”

According to Sean, the large data set – collected over five years – allow scientists to create complex models, using machine learning to understand how and why specific silk properties vary between species, and even between individual spiders.

“Just like the Human Genome project has given researchers the ability to identify specific gene sequence mutations that cause specific diseases, this database gives biologists and material scientists the ability to derive direct genetic causes for the properties of spider silk,” he says.

There are seven types of spider silk, secreted from different glands within a spider. Out of these, dragline silk is the crowning glory. Known for its strength, durability and flexibility, dragline silk has captured scientists’ imagination for decades with its tantalising potential.

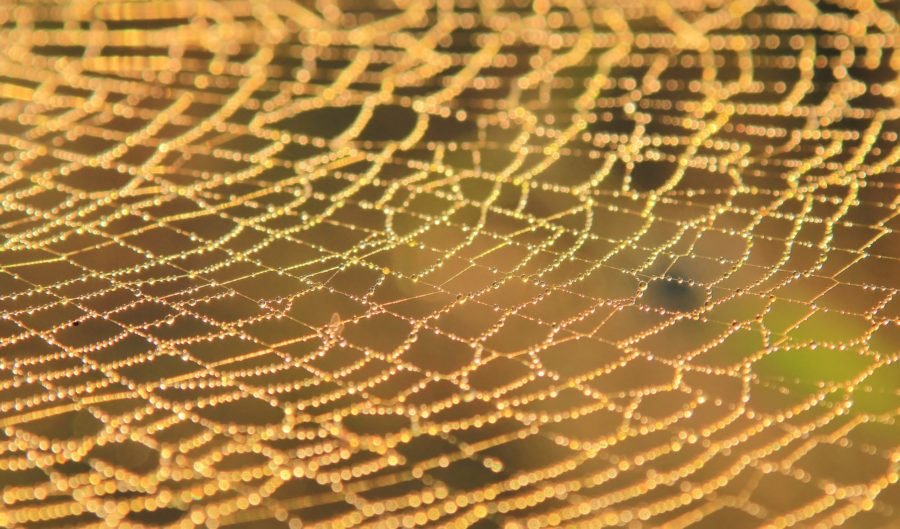

“In a spiderweb, the dragline silk makes up the framework and the radials. It’s also the silk that the spider uses when it drops off a web,” says Sean. “Non-web building spiders might use it to make retreats or use it for signalling with each other, while trapdoor spiders use something very similar.”

In Australia, the dragline silk produced by orb-weaving spiders is so tough that it outperforms Kevlar and steels. It’s tough, but also flexible.

“Most materials are either one or the other,” says Sean.

The study measured the mechanical, thermal, structural and hydration properties of dragline silks.

It’s hoped this research will provide a blueprint for renewable, biodegradable and sustainable biopolymers. Suggested uses for this lightweight material ranges from bulletproof vests, flexible building materials, biodegradable bottles, and even a non-toxic biomaterial in regenerative medicine, that can be used as a scaffold to grow and repair damaged nerves or tissues.